-

Product Center

-

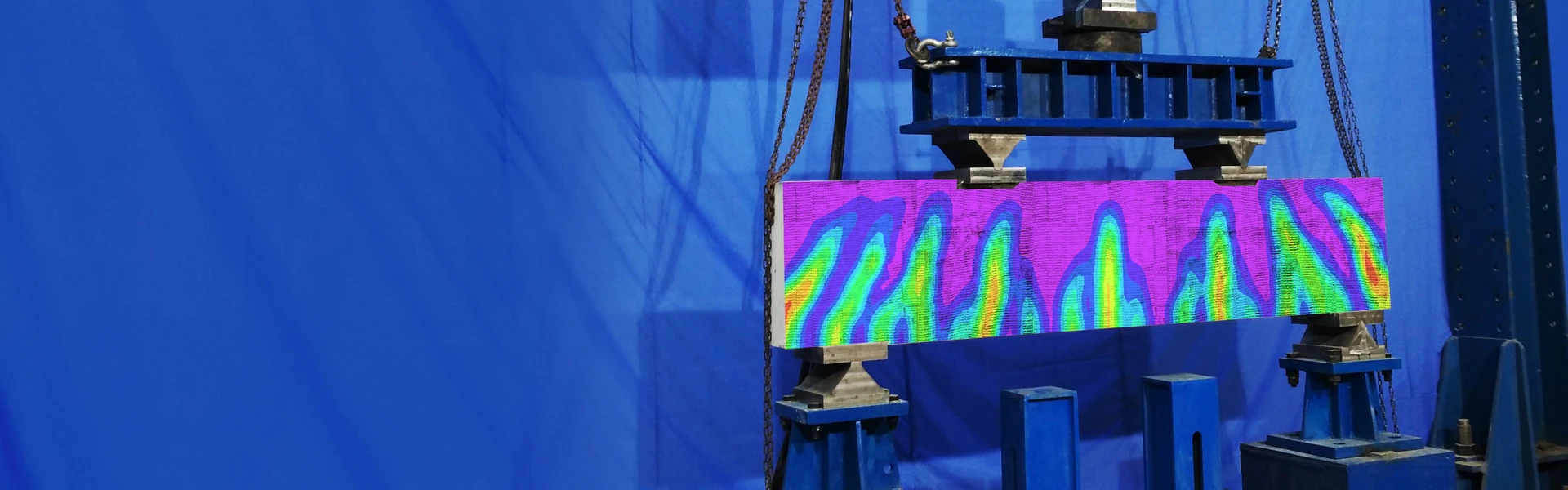

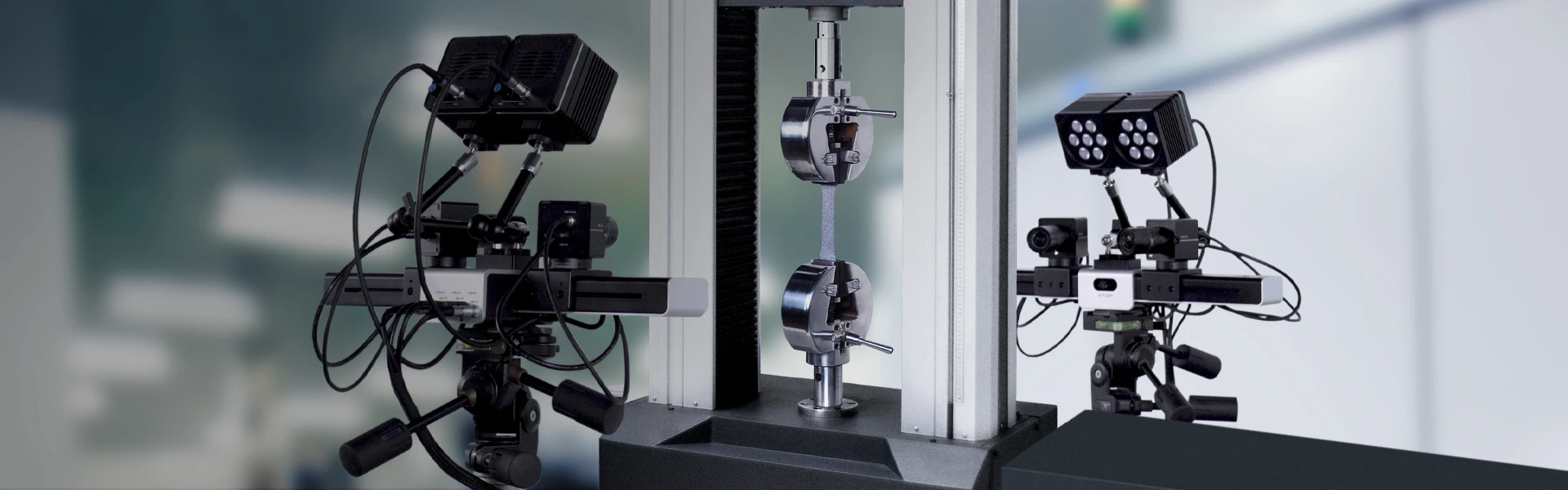

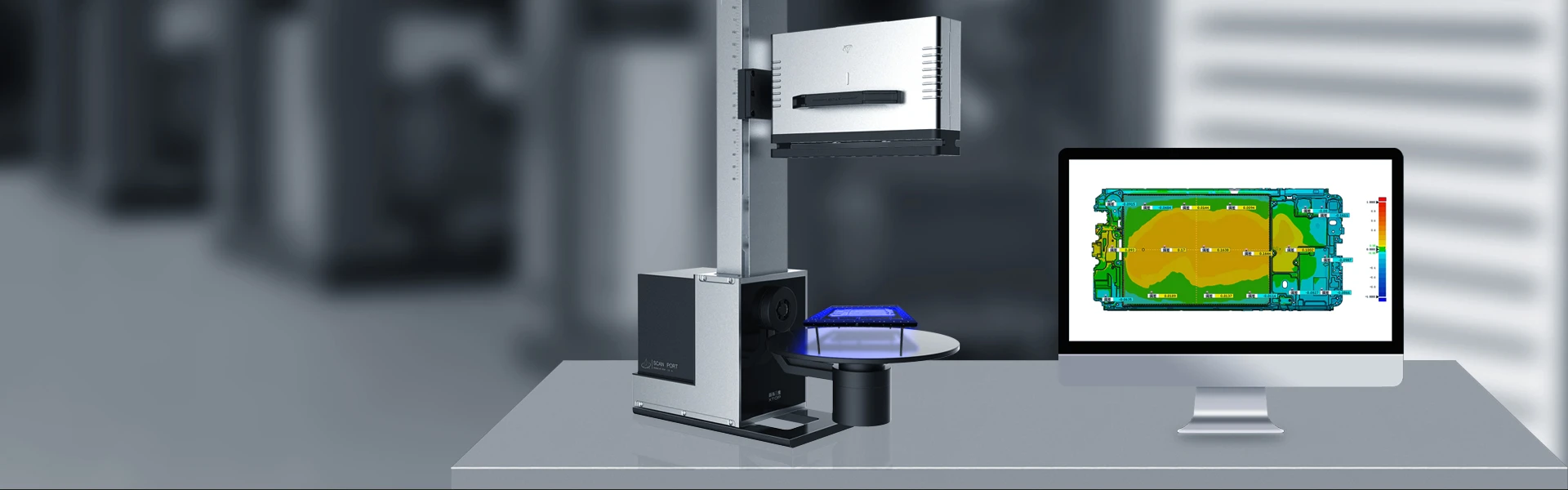

3D deformation measurement

-

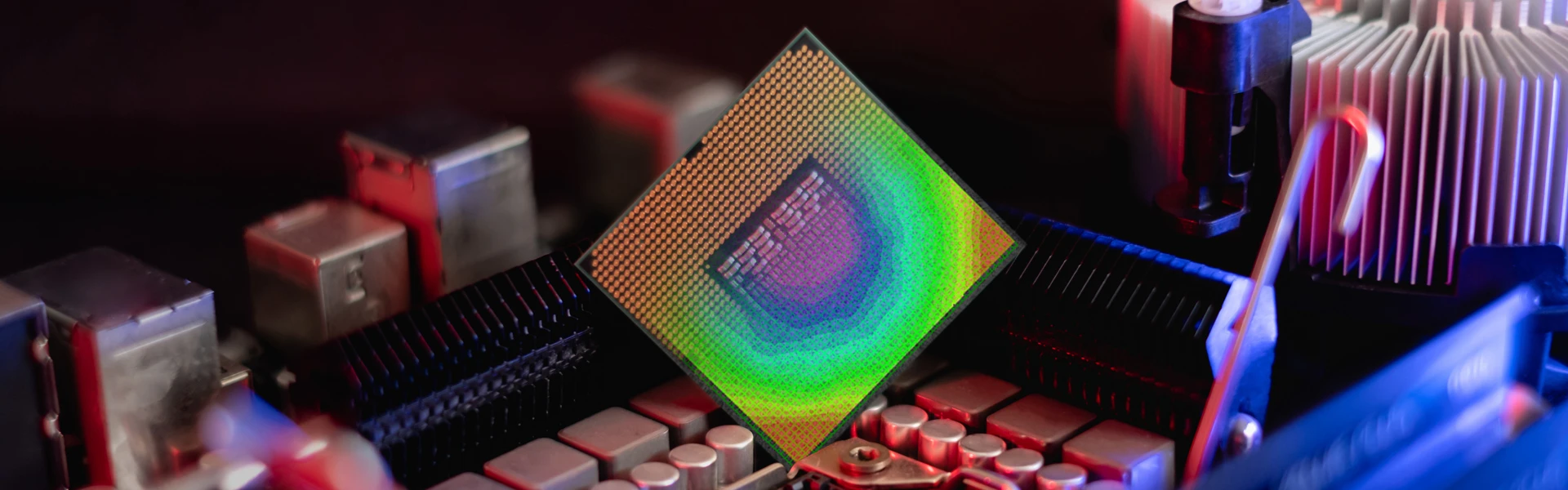

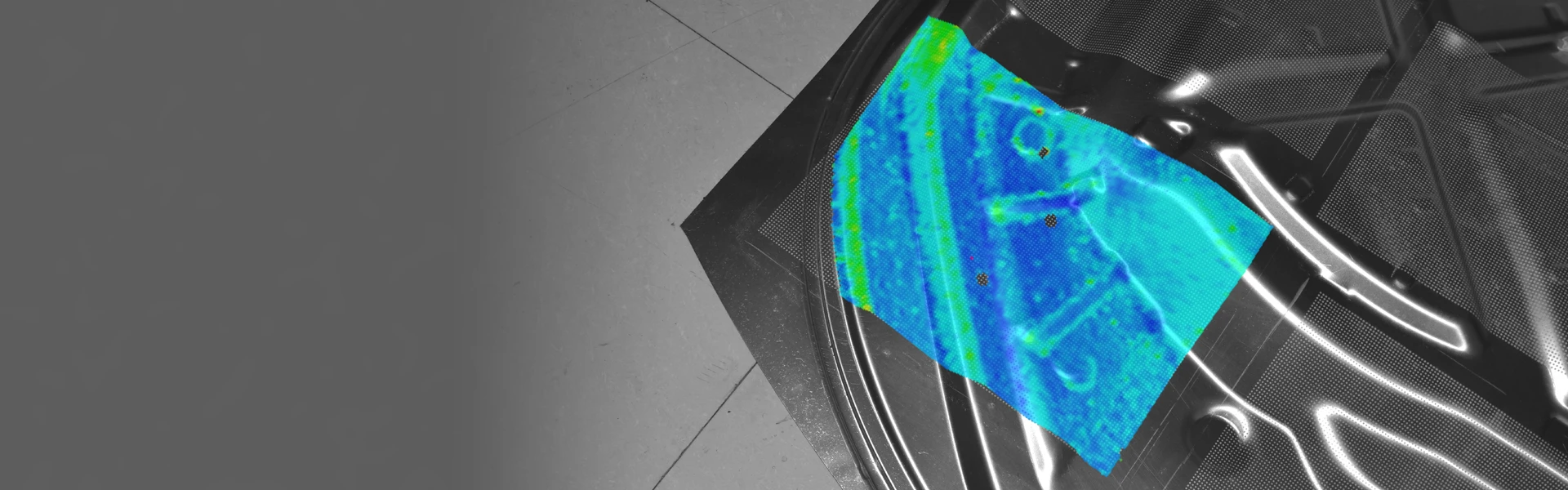

3D industrial inspection

Photogrammetry

-

Tube inspection

Tube measurement system

-

-

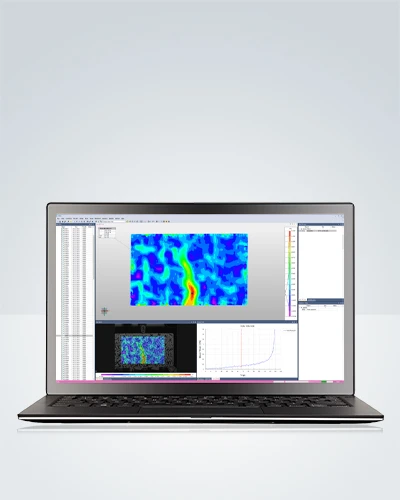

Software Platform

-

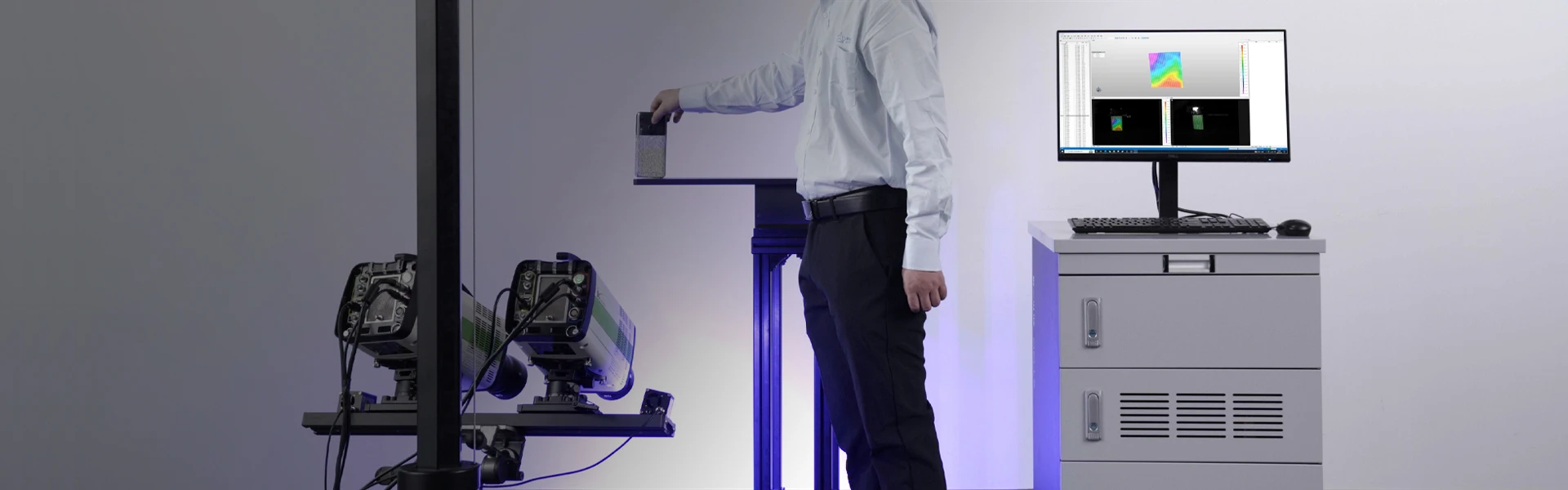

Application Software

3D deformation strain measurement

-

Vision Development Platform

3D Measurement SDK

-

- Solutions

- Deformation measurement

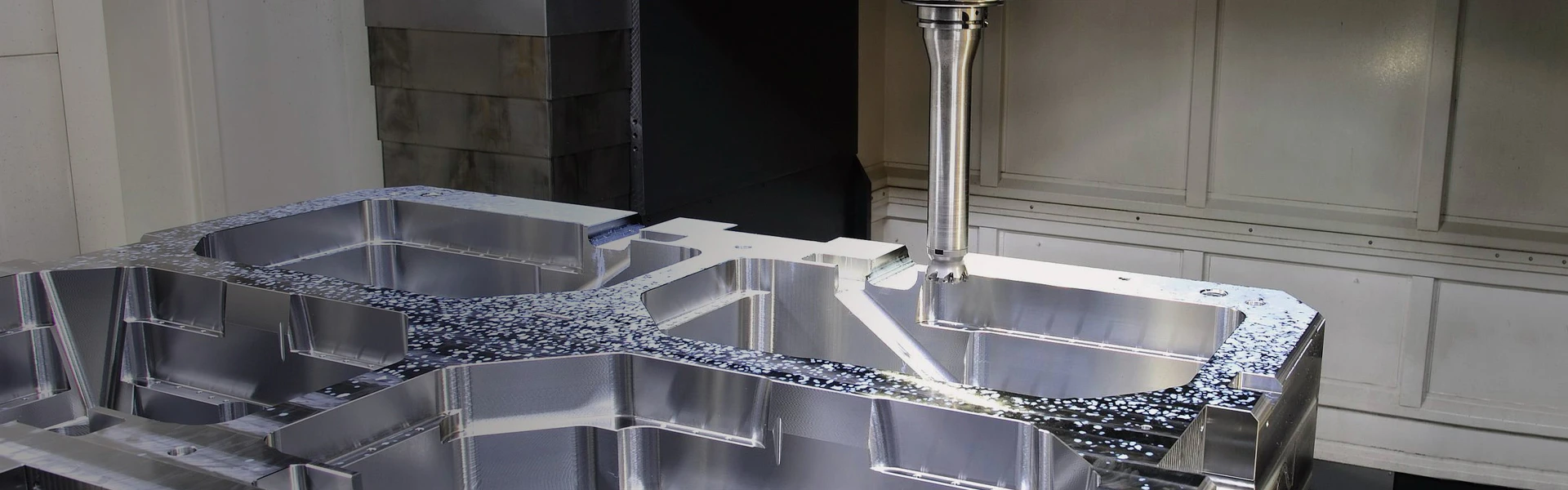

- Industrial Inspection

- Cases

- Accessories

- Service

- About Us